As a seasoned foreign trade professional with over 35 years of experience, specializing in paint roller sales, I am pleased to share insights into the often overlooked yet crucial aspect of paint rollers—their composition. In this comprehensive guide, we delve into the materials that form the backbone of most paint rollers. This article is not only about sharing knowledge but also empowering B2B buyers with the information they need to make informed choices.

What Are Most Paint Rollers Made Of?

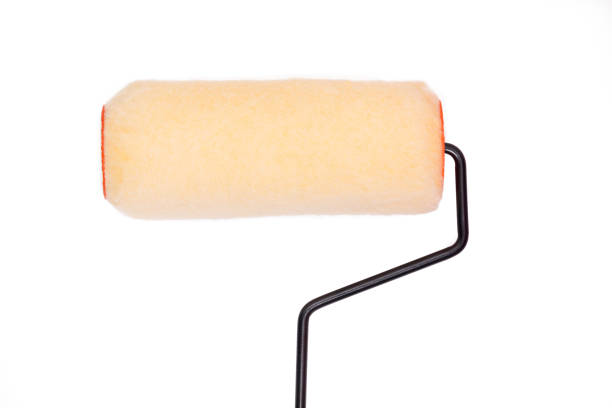

Most paint rollers are primarily composed of three key materials—fabric, frame, and handle. The choice and quality of these materials significantly impact the roller’s performance and durability.

Understanding the role of each material is essential for both professionals and B2B buyers. A high-quality fabric ensures effective paint application, a sturdy frame contributes to stability, and a well-crafted handle enhances control during painting tasks.

Fabrics for Superior Absorbency and Application

Polyester Fabric:

Professional Recommendation: Polyester fabric is a popular choice for paint rollers due to its excellent durability, absorbency, and versatility. It provides consistent paint application and is suitable for both water-based and oil-based paints.

Microfiber Fabric:

Enhanced Performance: Microfiber fabric is celebrated for its exceptional paint pickup and release capabilities. It holds more paint, resulting in reduced reloading frequency and ensuring a smoother, more uniform finish.

Blended Fabrics:

Versatility in Action: Some rollers feature blended fabrics, combining the strengths of different materials. These rollers offer a balance of durability, absorbency, and adaptability to various paint types.

Crafting Stability with Frames and Handles

Frame Materials:

Sturdy Foundation: Roller frames are commonly made from materials like steel or plastic. Steel frames provide durability and stability, while lightweight plastic frames offer ease of use and manoeuvrability.

Handle Construction:

Ergonomic Design: Handles play a pivotal role in the painter’s comfort and control. Ergonomically designed handles, often made of plastic or rubber, ensure a comfortable grip and precise manoeuvring during painting tasks.

Quality Assurance through Manufacturing Processes

Expert Assurance:

Stringent Manufacturing: A key factor in the quality of paint rollers is the manufacturing process. Reputable manufacturers adhere to strict quality control procedures, ensuring that each component is crafted to meet industry standards.

Professional Commitment:

Our Promise: With 35 years of experience in the industry, our factory is committed to delivering paint rollers that not only meet but exceed the expectations of professionals and B2B buyers. Our dedication to quality and innovation sets us apart in the market.

Elevating Painting Experiences with Quality Composition

In conclusion, the composition of paint rollers is a carefully orchestrated blend of materials designed to enhance performance, durability, and user comfort. Understanding the components empowers B2B buyers to make informed choices, ensuring the success of their painting projects.

Choose Quality, Choose Us – Your Trusted Partner in Paint Roller Excellence!

Explore our premium selection of paint rollers, meticulously crafted with industry-leading materials and expertise. Contact us today and experience the difference that knowledge, quality, and commitment make in the world of painting!