In-home improvement construction, we generally use roller brushes to paint the walls. How to use the roller brush to play the best effect, and how do the correct use and maintenance? In this article, we will introduce the relevant knowledge in detail.

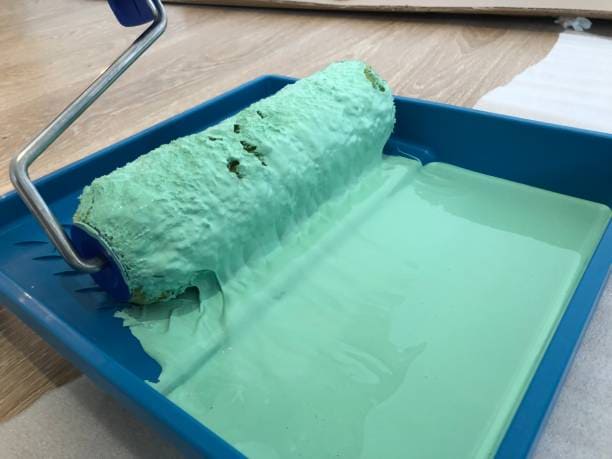

The roller brush, also called the paint roller, must be used with the paint roller tray. Because of the wide range of rolling surfaces, it is the most labour-saving, time-saving brush tool, especially after connecting the extension pole. It can easily paint the high part of the wall or ceiling, mainly for the construction of large-area paint roller coating. And can be used to apply and roll various blending paint, such as latex paint, rust-proof paint, interior and exterior wall coatings, wallpaper laminating glue, etc. To achieve the ideal construction effect, the construction personnel should master the use of a roller brush to give full play to the roller brush coating effect, but also should understand the roller brush maintenance methods to extend the life of the roller brush.

Roller Brush Materials

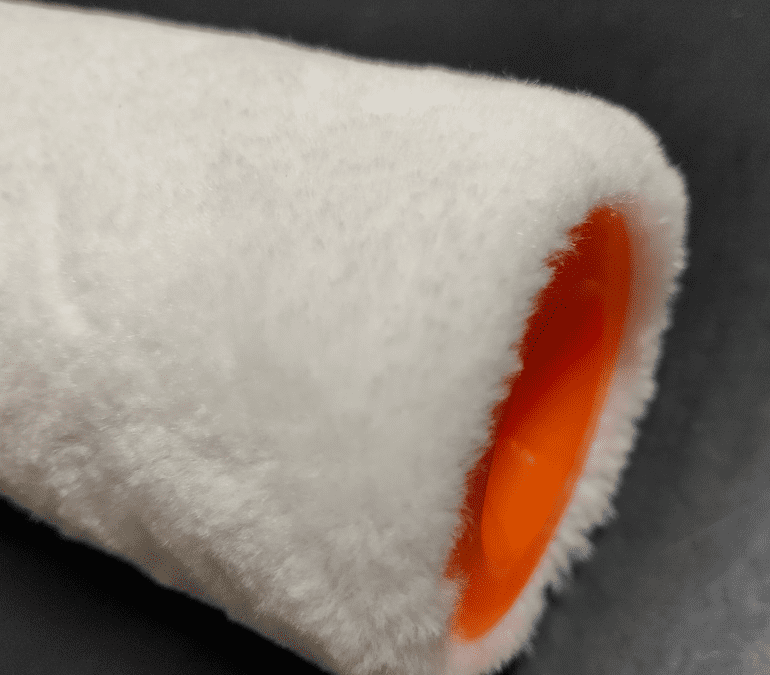

The material of roller brush is mainly made of wool and foam, so it can be divided into wool roller brush and foam roller according to the material.

The wool roller brush hair is usually divided into wool and chemical fibre class two, according to the length of the brush, hair is divided into long hair, medium hair, and short hair three; different roller brushes will paint different effects, long hair roller will paint some slight texture, a sense of bump, similar to the texture effect. The short-haired roller is more even, smooth and without bumpiness, and the medium-haired is in between. It can apply and roll all kinds of blending paint, such as latex paint, anti-rust paint, interior and exterior wall paint, wallpaper laminating glue, etc.

The material of the foam roller is a sponge, bristle, seaweed cotton, etc. The main one in the market is the sponge roller, divided into water-based and oil-based. Water-based sponge roller: PP inner tube and water-based glue, not resistant to thinner corrosion, only for water-based paint, generally with the 30-density sponge, good water absorption. Oil-based sponge roll: PVC inner pipe and oil-based glue, resistant to thinner corrosion, i.e. applicable to oil-based paints and water-based paints, usually with a 50-density sponge, less water absorption than a water-based sponge. Because the hydrophilic substrate of the microscopic linking stomata make it has good water absorption and water retention capacity, coupled with its unique softness, it can be widely used in printing plates, glass products, steel plates, aluminium plates and other panels of cleaning, pressure liquid, water absorption, dehydration process.

Roller Brush Sizes

The regular size of the roller brush is 2 inches, 4 inches, 6 inches, and 9 inches; other sizes and diameters can be produced according to customer requirements, different diameters of the sponge roller brush need to open the knife mould for cutting, and the diameter of the hair roller mainly lies in the thickness of the inner tube fittings and the thickness of the wool material.

the Use of a Roller Brush

The correct use method and operation steps are shown below:

1 Wash before use

Before using a new emulsion paint roller brush, be sure to clean the emulsion paint roller brush once with water and shake dry the water. This will clean the excess floating hairs on the emulsion paint roller brush. Before painting, the new roller needs to be wetted with a thinner material compatible with the paint.

Then, roll off the excess paint on a waste newspaper or clean the wall surface. This will facilitate the paint’s initial adsorption and the roller’s cleaning.

2 Dip the material evenly

When dipping the roller brush into the emulsion paint, ensure it is evenly applied. Jiao-paint, only half of the roller brush should be dipped into the material and then rolled back and forth on the roller tray screed board a few times to make the paint completely penetrate the cylinder sleeve. If you need more than the adsorption paint, you can dip it again more than once. Make sure the thickness of the emulsion paint on the surface of the roller brush is the same so that the emulsion paint can be painted more evenly;

3 Rolling skills

Rolling from top to bottom and then from bottom to top, roll the paint on the grass-roots level in a “W” shape, and then roll evenly horizontally; when the roller brush is dry, and then roll the surface gently, the width of each roll is about four times the length of the roller, and make one-third of the roller width overlap, so as not to form roll marks at the intersection of the coating film, to ensure uniformity of coating and save paint, the roller brush should be evenly applied at both ends of the roller brush, and the force can be slightly lighter at the beginning of the roller coating with more material, and then gradually increase.

Maintenance of a Roller Brush

Cleaning after use

Cleaning of the roller: The roller should be cleaned immediately after use so that it is not only easy to clean but also makes the cylinder sleeve less prone to deformation and prolongs the life of the roller. When cleaning, first wash off the paint on the roller and tray with water, then put some washing liquid in the tray, dip the roller into the washing liquid and shake it to let the washing liquid penetrate the lint of the roller sleeve, then take off the roller sleeve and squeeze out the washing liquid, rinse it in clean water until there is no colour, and rinse the roller with clean water. Put the washed sleeve back on the core, roll it on a flat surface to roll out the water quickly to loosen the lint on the sleeve, and place it in a ventilated and dry place so that it can return to its original shape and avoid the mould of the roller brush.

Today’s knowledge about roller brushes is introduced here, and I hope it will help you. To learn more about painting tools, please continue to pay attention to Paintbrusha.